In a laboratory setting, inventory management is a crucial, albeit boring process. You need to be aware of stock on-hand, inventory available for purchase, and all of the equipment, consumables, supplies, reagents, and other critical assets that are housed in your laboratory.

In this article, we’ll share with you some helpful tips and recommendations on inventory management in your lab, so that you can make the most efficient use of your available space, and reduce errors when it comes to monitoring equipment, inventory, and handling of bio samples.

A Quick Checklist for Lab Inventory Management:

You can reference this checklist while optimizing your inventory management system, but we’ll also explore each bullet point more in-depth further below.

Ensure an accurate stock list. Acknowledge your min-max stock levels. Categorize your inventory items. Strategically organize physical space. Have management procedures in place.

Ensuring an accurate stock list:

Inventorying a laboratory is no easy task, but it’s an essential process to keep your laboratory functioning optimally. So you should start with an accurate stock list that lays out your requirements, and you can build out from there. When it comes to developing your inventory list, take a look at the different parts of your laboratory, and write down a list of:

Items in low-turnover or excessive quantity. Items that are in high-demand. This will help when you do stock audits, which you should also perform regularly to check for accurate inventory and accurate in-stock allocation of inventory.

Use inventory tracking software to help you with managing lab inventory effectively – it will reduce most human errors, and give you far better insight into what stock is actually in-hand.

3) Categorizing your inventory items.

Once you have a correct min-max inventory count, it’s time to categorize your inventory items. This will help a lot if you’re using inventory management software, so that you can easily add tags to items such as consumables, hazardous substances, and reagents.

It’s a great way of getting an overview of all items in sub-categories, for a more minute level of analysis, and you can use this to highlight your inventory bottlenecks, as well as increase efficiency in the handling of laboratory assets.

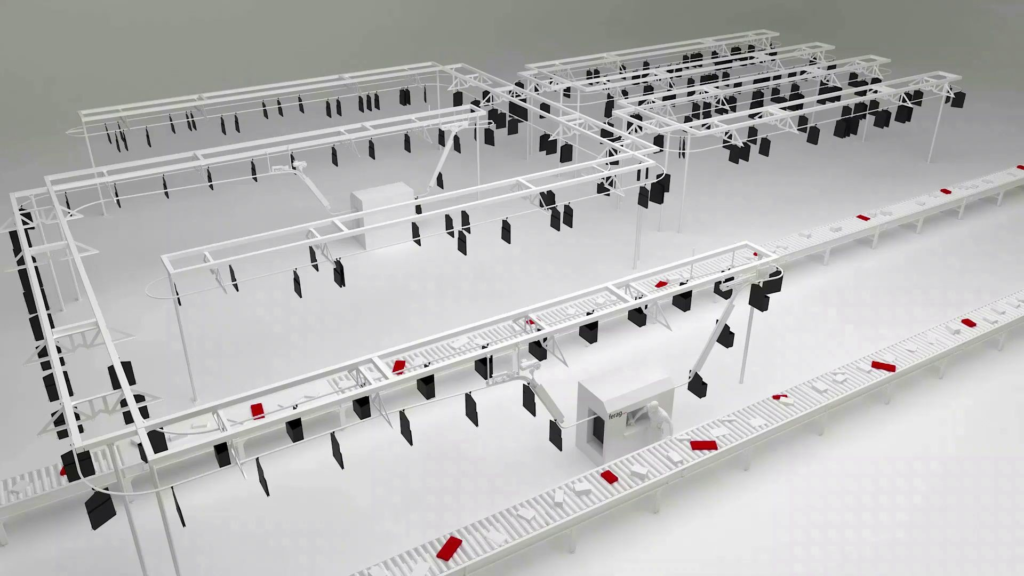

4) Strategically organizing physical space.

Having an efficient inventory management system isn’t very helpful if your lab is cluttered, messy, and disorganized. So you should aim to strategically organize your physical space, as well as your labware in-hand, with the aim of maximizing efficiency.

You should have dedicated shelving or storage that contains the items you will need to be able to test, and this area should be clearly labelled so that it is clear where all of your lab equipment is located. Also be sure to disaster-proof your inventory storage areas.

You should also have dedicated labware units (equipment containers) in the lab for holding your equipment and other lab supplies. These should be labelled as well, with the lab’s name so that it is clear which items belong to which lab, and what items are being stored.

5) Have inventory management procedures in place.

Your staff should be familiar with the various procedures that are necessary for inventory management, and these should be clearly communicated to them. This way, you can ensure that there are no gaps in any knowledge or procedure, and that the staff are all working in the same direction.

This will help you in the future, as you can compare the effectiveness of different protocols or procedures, and you can easily identify bottlenecks and points of friction in your inventory management processes.