Working in one of the most demanding markets in the world, Retech has become a global leader in metallurgical processing equipment supply. In short, its technical acumen, customer service, and dedication to reliable machinery that its clients can trust has made it a true front-runner, allowing it to pull ahead of the competition to serve clients across the metalworking industry, including those working with super alloys and rare earth metals. Having successfully made itself the ‘Most Innovative Metallurgical Equipment Specialists’ in 2022 for the USA, it looks forward to continuing to take the international industry by storm.

Having been in operation since 1963, Retech is a company emboldened by the knowledge of the past and the innovation of the future. Its industry, the global metallurgy sector, is demanding and ever-changing, and thus Retech has dedicated itself to keeping its finger on the pulse of these changing demands and developments so that it can continue to be competitive and relevant to what its customers need. Since its inception, Retech’s advanced processes and technologies have been bought and used by the foremost experts in melting, refining, and casting reactive and refractory metals, from titanium and titanium alloys, super alloys, and rare earth metals. As expected, this has all empowered it in its mission to become the premier supplier of equipment for advanced thermal metal processing in controlled atmospheres.

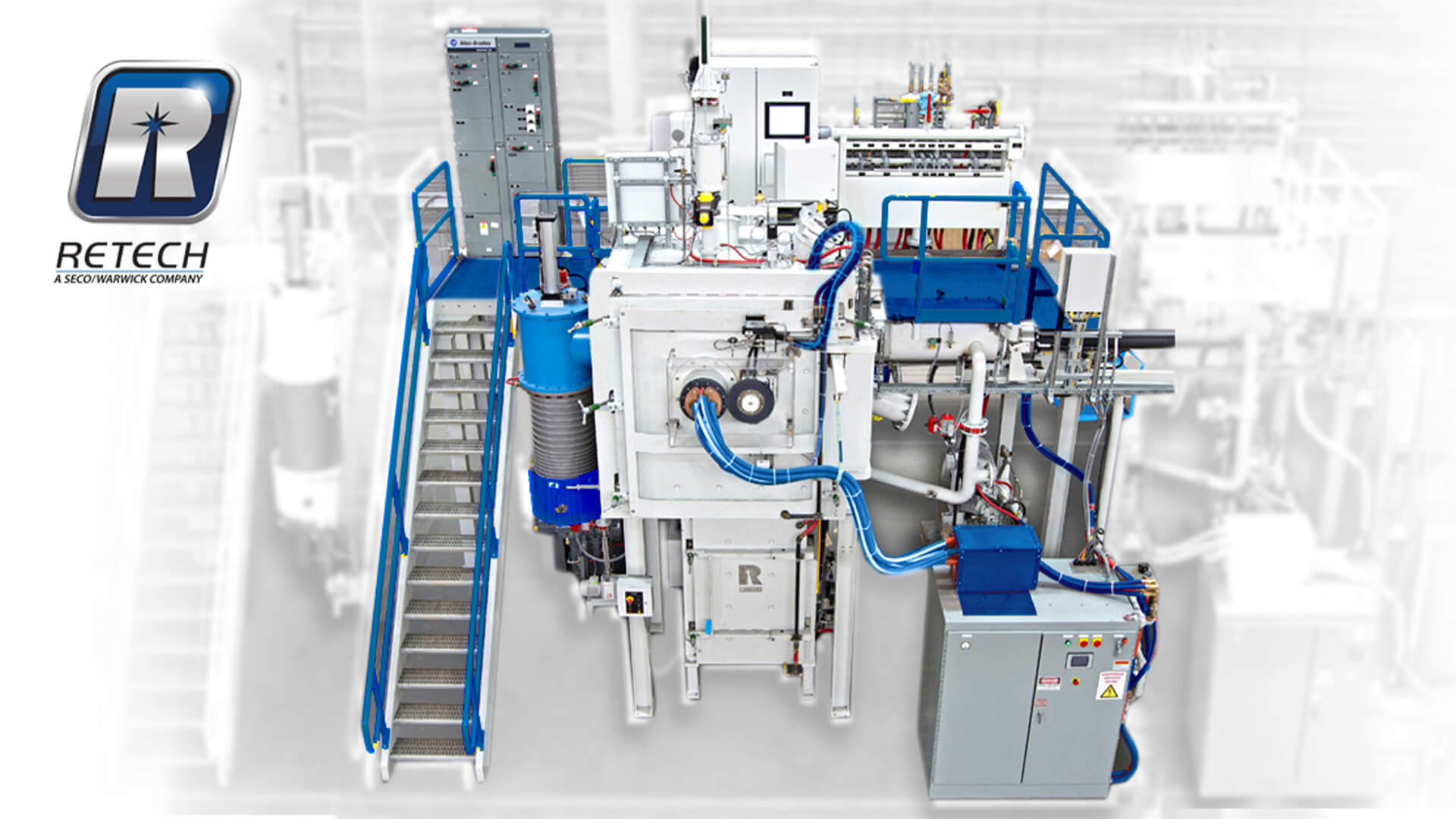

In addition, Retech has pioneered new applications for electron beam cold hearth melting, plasma cold hearth melting, and cold wall induction, showing its industry its adaptability when it comes to the types of systems and their applications. Having developed a critically important solutions for its industry in the Rototrode non-consumable arc and Plasma Arc Centrifugal Treatment – or PACT – it has garnered an outstanding reputation for engineering customised, tailor made, and reliable system products with unique metallurgical and geometric properties that are required by nature of the application.

In terms of the Retech mission, it has been focused on the creation of innovative products that provide customers with the safest, most dependable, and most environmentally responsible metallurgical solutions on the market. Critically, it recognises that this is a mission with goalposts that are ever-shifting due to the exponential nature of innovations, and it is excited by this fact, always looking to improve, develop, and grow both as a company as well as a dedicated group of professionals who are passionate about metalwork. With the experience of its employees, the co-operation of its business partners, and the support of its customer base, it is the Retech promise that every product it delivers will be safe, efficient, and effective.

Essentially, this is a point of honor for the team behind Retech, and something it seeks to show by operating with integrity in everything it does. This has earned it a huge amount of return customers for whom it is their trusted one-stop-shop for metallurgical machinery, with more new clients in the aerospace and defense industries coming to it daily. However, despite these traditional industries being the most common amongst its clientele, Retech has been seeing a growing interest in its work from the medical and recycling industries, as well as those that use energy-intensive materials and powdered metals, many of whom are seeking more sustainable fabrication methods. Thus, its efforts in outreach are predominantly in relationship building with current clients, allowing them to become not just customers, but lifelong partners.

Because of the focus on relationship building with customers, as an alternative to individual sales, Retech has a relatively small, but loyal, customer base when compared to many other industries. However, this is not a pitfall, but a feature that commands respect, as it fosters the success of its customers through its relationships within niche markets and cultivates a small, specialist clientele that it will always go above and beyond for. Most current market participants in the niche fields it invests in have been, are, or will be Retech customers at some point, and its customizable nature has made it the best choice for companies with highly specific needs.

Its skilled, dedicated, and dependable staff often wear multiple hats, and are invigorated by the challenge of serving such a myriad of different clients, all of whom request hugely different things that tell a tale of their specific corporate mission. Therefore, it hires people who are exemplary team players and great communicators, as well as those who believe in pushing the envelope in an industry to continually make it a better place for both the employees within it and the end user of the created items. These people then go on to shape the culture into something comfortable, respectful, and diligent, something that has aided it in its staunch survival of the Covid-19 pandemic.

Despite the niche nature of its industry, having only three key suppliers – of which Retech is one – it is profoundly affected by changes in supply and demand, both of which were impacted greatly during the outbreak and have been on a slow recovery ever since. Thus, working with airplane groundings, material issues, and a need for alternative production methods, Retech found a need to become more efficient and to cut the fat from many of its processes, a metamorphosis that has ultimately been to its benefit despite the initial tumult. This means that it is now able to continue empowering its work and improving its services, and that it will be continuing with its research and development, excited to dive into the nitty gritty of customers looking to capitalize on its capabilities.

For business enquiries, contact Christopher Jackson from Retech on their website – retechsystemsllc.com